Reducing Manual Chaos: How Intelligent Automation Is Reshaping Manufacturing Ops

What’s in This Blog?

- Why Manual Chaos Still Exists in Modern Manufacturing

- What Intelligent Automation Really Means

- What a Production-Ready Intelligent Automation System Looks Like

- Step-by-Step Roadmap to Move from Pilot to Scale

- Ownership and Operating Model: Who Runs Automation Day to Day

- Final Thoughts

- FAQs on Intelligent Automation

Most manufacturing ops still run on manual processes. Work orders are tracked in spreadsheets. Quality data logged on paper. Inventory counts are done by hand.

It creates problems. Information gets lost between shifts. Decisions get made on old data. Small errors multiply.

Intelligent automation changes the equation when it’s applied at the process level, not the task level. It connects data across OT and IT. It removes handoffs instead of digitizing them. And it forces teams to be clear about outcomes before touching tools.

This post breaks down how intelligent automation is actually reshaping manufacturing operations today. Where manual work hides. Where processes create the most operational drag. And how leading teams prioritize, design, and scale automation without disrupting the floor.

Why Manual Chaos Still Exists In Modern Manufacturing

Manual chaos persists because most factories have improved visibility, not execution. Dashboards exist, but daily work still depends on people moving data between systems. This leads to downtime from late signals, rework from mismatched specs, repeated data entry, and long lead times.

The problem is structural. OT data does not flow into planning, quality, or maintenance. KPIs are misaligned, so teams optimize locally instead of end-to-end. Production data is inconsistent, making automation unreliable. Silos force people to fill the gaps. Until these foundations are fixed, chaos remains.

Definitions and Scope: What Intelligent Automation Really Means

Intelligent Automation in manufacturing is not about replacing people or bolting AI onto existing processes. It is about connecting data, decisions, and actions across the operation so that work can be done with minimal manual intervention. Systems sense what is happening, decide what should happen next, and trigger actions automatically or with human approval where needed.

What a Production-Ready Intelligent Automation System Looks Like

A production-ready system is built to support daily operations, not demos. It connects data, decisions, and actions across the plant with minimal manual intervention.

Data foundation and integration

Automation depends on reliable shop-floor data reaching planning, quality, and maintenance systems in near real time. PLC and SCADA data must be standardized, contextualized, and accessible. If this layer is unstable, everything above it fails.

Sensing and IIoT

Instrumentation should focus on constraint equipment, quality-critical processes, and high-failure assets. The goal is to capture machine states and events that explain performance variation, not to collect data indiscriminately.

Edge compute and inference

Edge systems handle time-sensitive use cases such as anomaly detection and in-line quality checks. Models must be versioned and updated without disrupting production.

Digital twin and simulation

Digital twins are used to test line changes, validate schedules, and run what-if scenarios before execution. They reduce risk by exposing issues early.

Automation and orchestration

Decisions must trigger consistent actions across MES, planning, and workflow tools. Clear rules for approvals and exceptions prevent manual rework.

Monitoring and feedback

Ongoing monitoring ensures data quality, model performance, and business KPIs remain aligned over time.

Step-by-Step Roadmap to Move from Pilot to Scale

This roadmap reflects how manufacturing teams move automation into daily operations and keep it there.

Phase 0: Opportunity Scoping

Select one operational problem that directly impacts throughput, quality, or cost. Define the smallest measurable outcome that can be validated within 60 to 90 days. Score the opportunity on business impact, data readiness, integration effort, and ownership. If success cannot be measured clearly, the effort will stall.

Phase 1: Pilot Design

Define a clear hypothesis and success criteria before building anything. Establish a baseline and, where possible, a control group. Document data sources, data frequency, and quality requirements. The pilot should prove value, not explore possibilities.

Phase 2: Productionize

Prepare the system for daily use. Finalize integrations, define API contracts, plan for failures, and establish operational ownership. Reliability and recovery matter more than model accuracy at this stage.

Phase 3: Operate and Improve

Track service levels, system performance, and cost. Monitor outcomes against business KPIs. Set a regular cadence for review and model updates.

Phase 4: Scale

Standardize what worked. Create repeatable patterns for rollout across sites. Centralize model operations and define a clear CoE charter to support adoption and governance.

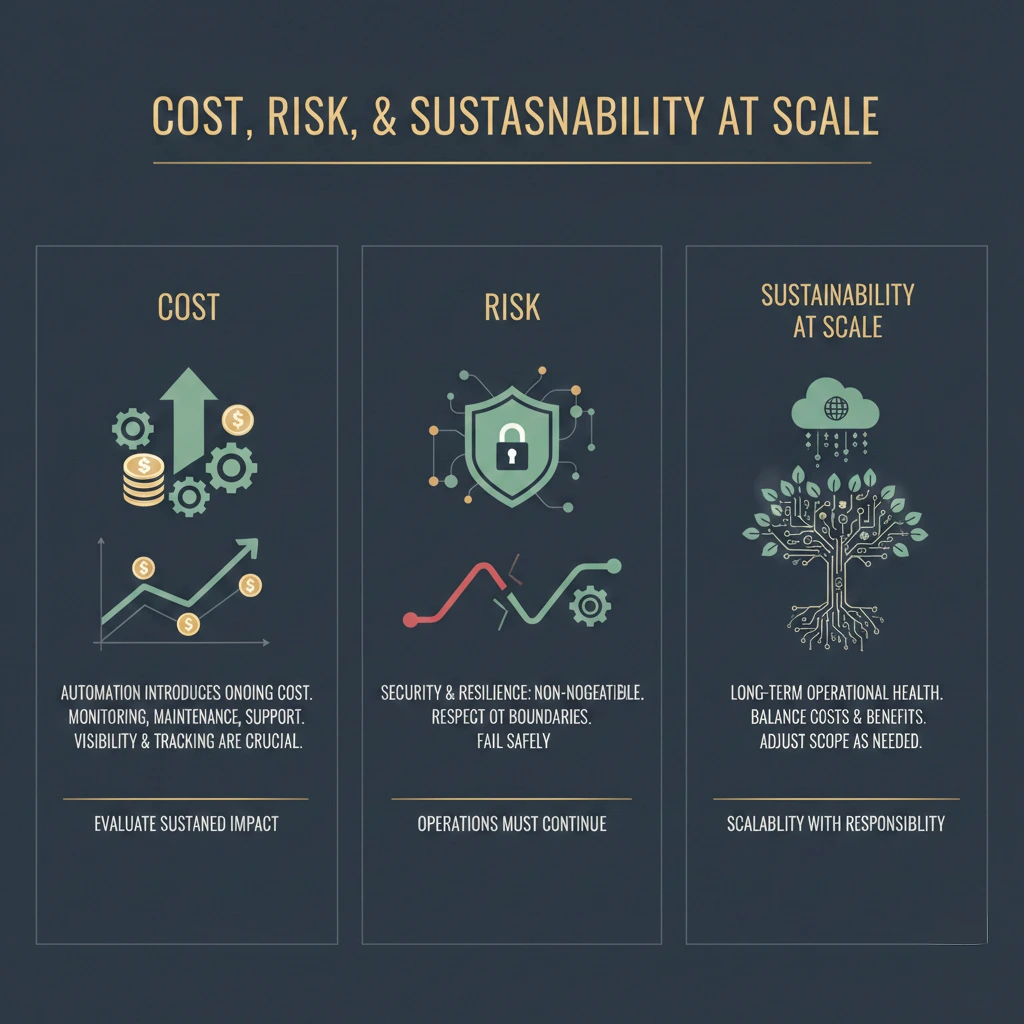

Before scaling automation across plants, leaders need to confront three realities that determine long-term success: cost discipline, operational risk, and sustainability. Ignoring any one of these turns automation from a performance lever into an operational liability.

Ownership and Operating Model: Who Runs Automation Day to Day

Automation fails when ownership is vague. Someone must be accountable for outcomes, not tools. In production environments, operational leaders own performance. IT and data teams enable reliability, security, and scalability.

Clear roles matter. Operations define success metrics and escalation paths. IT maintains integrations and infrastructure. Data teams manage models and data pipelines. Decisions about changes, rollbacks, and exceptions must have named owners.

Without a defined operating model, automation becomes a side project. With one, it becomes part of how the plant runs.

Final Thoughts

Most manufacturing teams are not struggling with ideas. They are struggling with execution. Manual handoffs, delayed decisions, and fragile pilots continue because automation is added without fixing how work actually flows.

Intelligent automation delivers value only when it is built around clear outcomes, reliable data movement, and operational ownership. Teams that get this right reduce downtime, shorten lead times, and free operators and planners from constant firefighting.

The shift is not about more technology. It is about building systems that run consistently on the shop floor and scale across plants.

Ready to move from pilot projects to production-grade automation?

Talk to our experts to design and scale intelligent automation that delivers measurable operational results. The Commerce Shop helps operations teams turn automation into repeatable, scalable execution.

FAQs on Intelligent Automation

1. Is intelligent automation the same as traditional automation?

No. Traditional automation executes predefined rules. Intelligent automation combines real-time data, analytics, and AI to adapt decisions based on changing conditions on the shop floor.

2. Where should manufacturers start to reduce manual chaos?

Start with one high-impact operational constraint, such as downtime on a bottleneck asset or manual planning handoffs. Define a measurable outcome before selecting any tool.

3. Do we need clean, perfect data before automating?

You need reliable and consistent data, not perfect data. However, unresolved data gaps or inconsistent identifiers will limit what automation can safely control.

4. How long does it take to see results from intelligent automation?

The initial value is typically visible within 60 to 90 days for focused use cases. Broader operational impact usually follows within 6 to 12 months.

5. Does intelligent automation replace operators or engineers?

No. It reduces repetitive work and decision delays. Operators and engineers remain responsible for oversight, exceptions, and continuous improvement.

6. Why do many automation pilots fail to scale?

Most fail due to weak integration, unclear ownership, lack of operational KPIs, and no plan for long-term monitoring and governance.

- Artificial Intelligence (1)

- B2B (3)

- manufacturers (9)